This service is recommended for those who:

We have obtained JIS Q 9100 certification, a quality control standard for the aerospace field.

Certificate Number: JQA-AS02054

Scope of Registration: THE ADDITIVE MANUFACTURING FOR AEROSPACE AND DEFENSE

Registration Date: October 23, 2020

JIS Q 9100: 2016*

*JIS Q 9100: 2016 is technically equivalent to AS9100D and EN9100: 2018

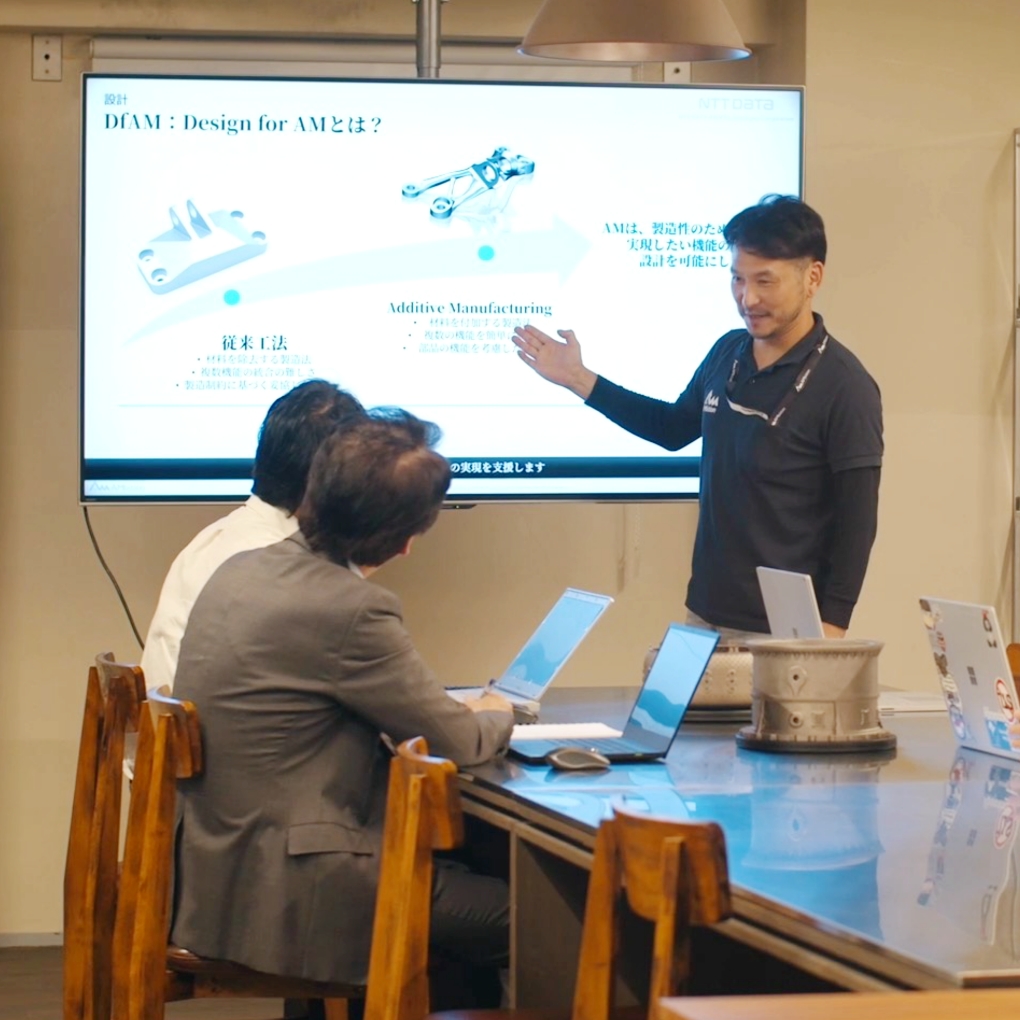

People tend to think that 3D printers can print any shapes, but just as every manufacturing method has its own shapes that it is good at or bad at, there are shapes that are not suitable for metal AM. Not suitable shape means a shape that does not take full advantage of AM, and in some cases, the traditional method may produce better results.

Our strength is that we can propose what parts can maximize the benefits of AM and what design changes can be made to create added value.

The design solution is to do DfAM*, but it can also be solved by developing laser exposure parameters.

Selecting parts to be manufactured by AM from the standpoint of economic and technological viability

Redesigning 3D data for AM

Proposing of design and geometry optimization considering productivity and printability

Verifying designs by FEM analysis (Static/ Thermofluidic)

Designing considering deformation due to residual stress

Leveraging next-generation design technologies such as topology optimization and metamaterials

Laser Powder Bed Fusion (LPBF) is completely different manufacturing method compared to existing one, that means we get different material properties even if you use same material. Metallographic structure also depends on the parts geometry. Each material type has different laser absorption rates and that is one of the reason why metal AM has unique mechanical properties.

Metal 3d-printing has tons of process variable. Mechanical properties will change dramatically when you change an element of process variable. In other words, if we deeply understand the whole process, we can get the mechanical property we want.

By adding our metallurgy knowledge to process knowledge, we develop new 3d-printable material. We are good at developing material and process that our customer requests and there are some patented material in our material portfolio.

Developing processes to meet your specific requirement

Controlling parameters by visualize heat input during 3d-printing

Simulating deformation due to residual stress, offering the best geometry

Designing your specific metal alloys

Developing parameters with your specific materials and validate that printability

Evaluating metallographic structure at the micro level

Developing conditions of heat treatment to meet your requirement

In addition to shortening development lead times, 3D printers also have the advantage of enabling performance-driven design because they can 3d-print geometries that previously could not be manufactured.

However, it is not a technology that you can just push the start button and the product will come out exactly as drawn data.

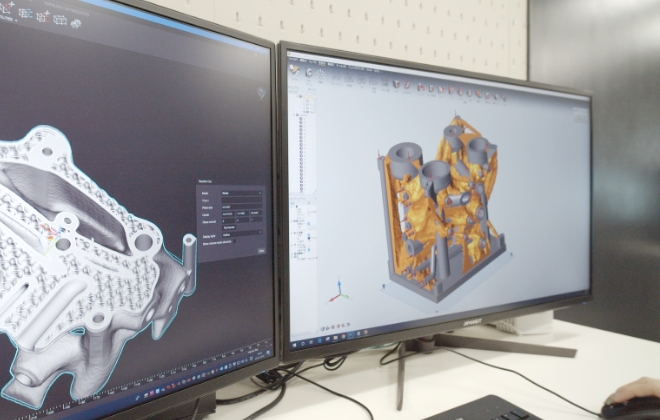

In the 3d-printable area, parts can be oriented freely in three dimensions, but their layout affects surface roughness, internal quality, productivity, and deformation from internal stresses.

Therefore, it is necessary to consider the exposure dimensions of each layer and adjust the input energy of the laser.

However, changing the amount of laser energy will also change the quality of the parts, and that need to be evaluated.

Complex channels can be 3d-printed with 3D printers, but the process allows the material powder stays in the internal channels. Therefore, it is important to devise 3d-printing plan by considering powder removability as well.

Proposing DfAM and redesigning 3D data

Reducing deformation by utilizing process simulation

3d-printing in high quality and high accuracy with our years of process development

Managing and validating process by utilizing digital technology

Devising 3d-printing plans by considering powder removability

Devising 3d-printing plans for mass-production*

| plans for mass-production |

|

|---|

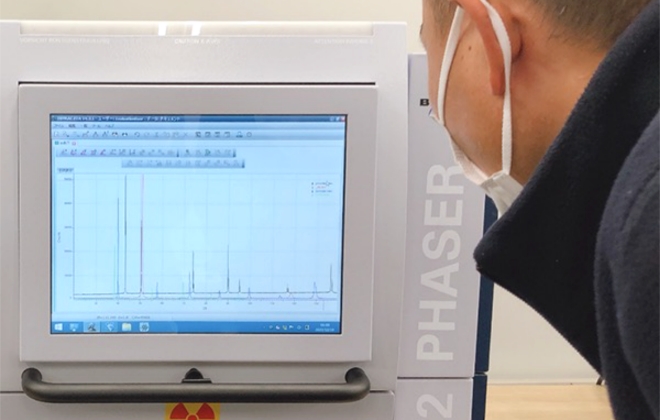

We need to control the process because metal AM is categorized as special process.

That means, there are so many things to inspect and control, including whether the machine works properly and whether the properties of material powder itself are right.

When printing the same parts at a time, different results may be obtained for each part depending on the production position and exposure parameters. Therefore, it is necessary to inspect every part produced. If any non-conformity parts are found, the cause should be clarified, and the project should be returned to parameter development.

Both destructive and nondestructive testing are needed to clarify if there are internal defects. If the 3d-printed parts have any problems, new controls need to be added on process control.

It seems very difficult to utilize AM technology, but you can say if you control the process correctly, you can manufacture parts at the completely same quality. This is a highly repeatable technology.

Inspecting and evaluating process, material and 3d-printed parts

Providing process management using in-process monitoring system

Analyzing the cause of 3d-print fails and devising countermeasures

| Powder materials | Mechanical property | Dimension size and appearance inspection |

|---|---|---|

| Scanning Electron Micrography analysis | Tensile strength | 3D measurement (contact/ non-contact) |

| Fluorescent X-ray analysis | Specific gravity | Wall thickness |

| Powder particle size distribution | Hardness | Endoscopic inspection |

| Powder flow rate | Surface roughness | |

| Oxygen-Nitrogen analysis | Conductivity measurement | |

| Cross-section observation | ||

| Metallographic analysis | ||

| Oxygen-Nitrogen analysis |